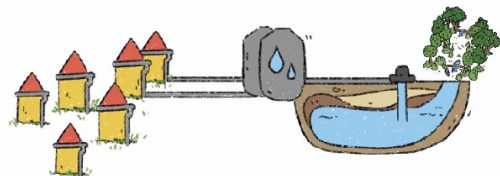

HYDRO1 consists of a sewage treatment system applied in decentralized areas with high seasonal loads.

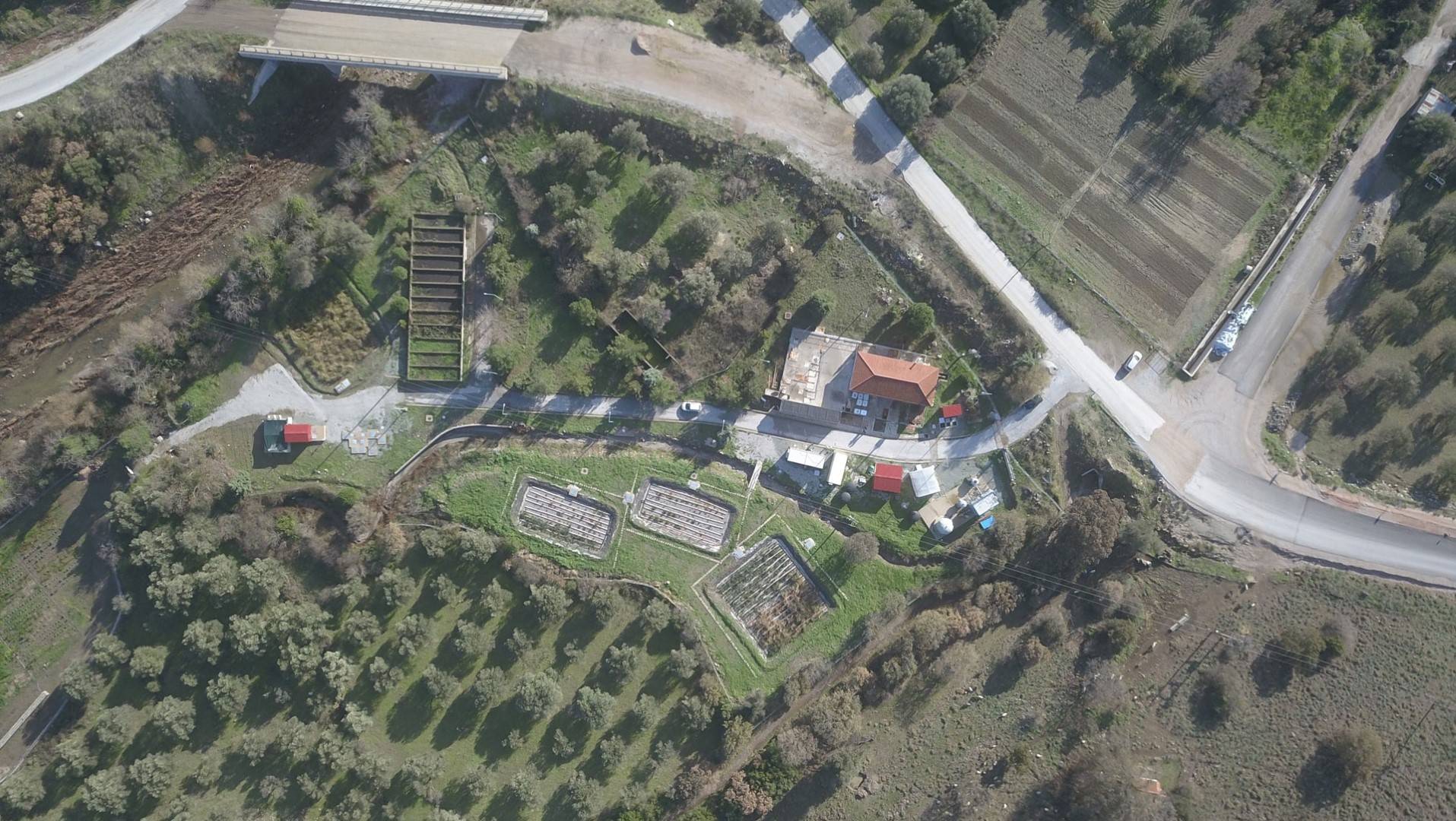

The demo site treats the domestic wastewater of Antissa village wastewater treatment plant (WWTP) located at the island of Lesvos, Greece.

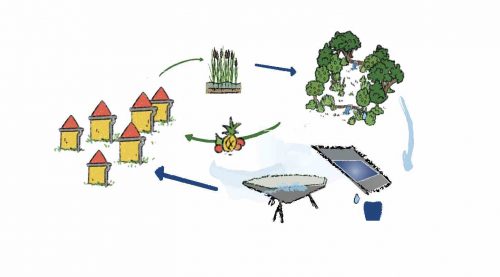

HYDRO1 combines anaerobic processes with constructed wetlands and disinfection to treat domestic wastewater as a completely circular solution where water, nutrias and the produced sludge are reused. Furthermore, the anaerobic process recovers energy in the form of biogas, which is then upgraded to produce high purity methane used to fuel local vehicles.

Municipality – Community

Municipal Wastewater

Compost, Biogas, Reclaimed water for fertigation

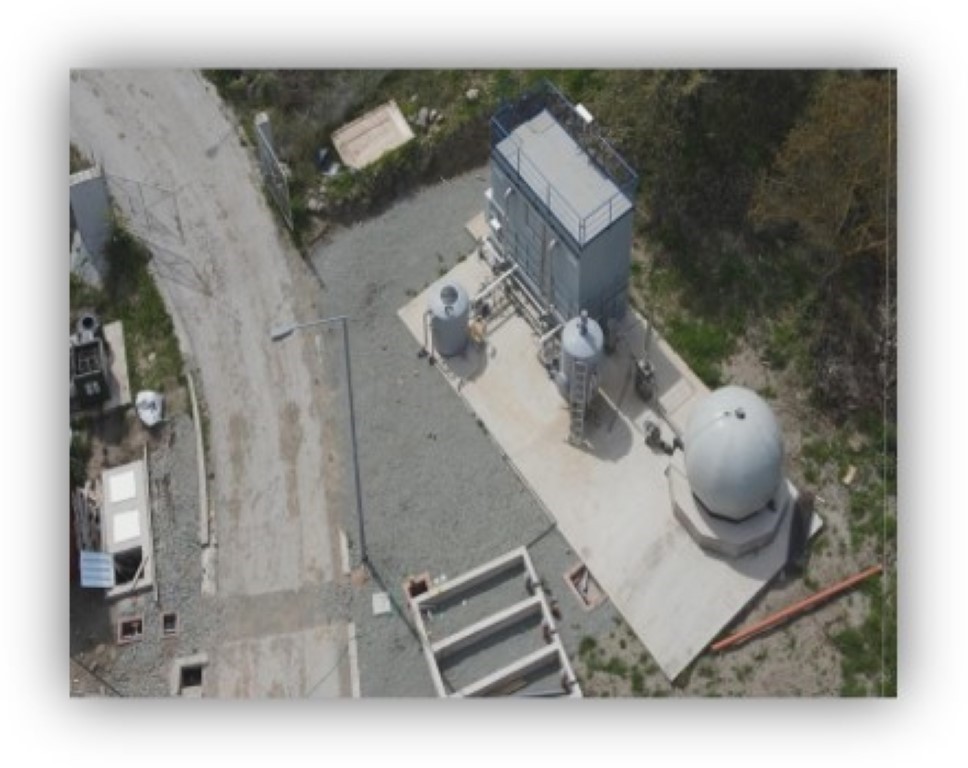

HYDRO1 consists of a wastewater treatment train with a maximum capacity of 100 m3/d (anaerobic treatment stage followed by vertical flow constructed wetlands and post treatment units), a biogas upgrade system, a composting unit and four novel pilot scale constructed wetland systems.

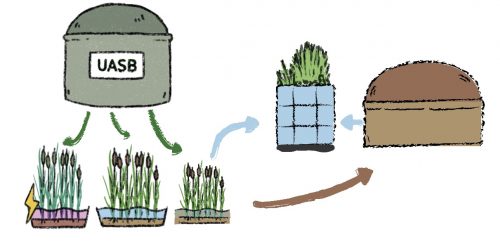

The anaerobic treatment takes place in two UASB reactors, leading to the production of biogas and a small amount of sludge. The process recovers energy in the form of biogas, has low operating expenses and low footprint requirements. The biogas produced is collected in a gasometer and is being upgraded in order to produce pure biomethane which will be used as fuel, while the sludge is treated in a sequence of a sludge drying reed bed and a composting unit.

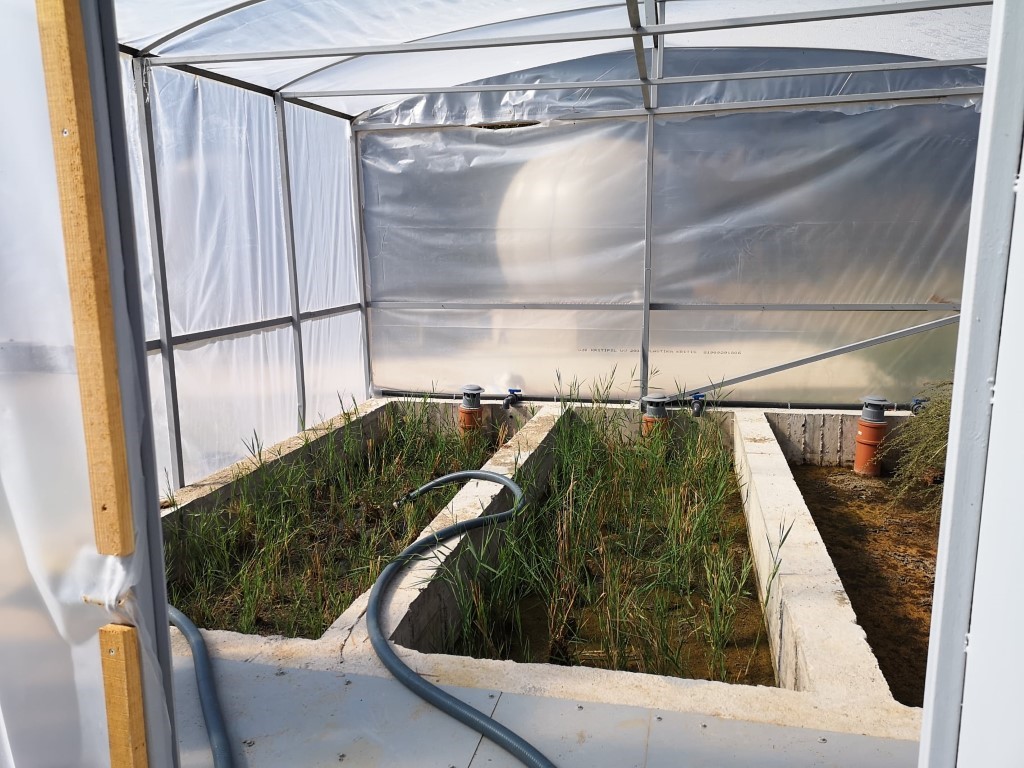

The anaerobic treated effluent is fed in the constructed wetlands, which serve as a secondary treatment providing further reduction of the organic carbon content and suspended solids of wastewater. The treated effluent from the wetlands is further fed to a post-treatment unit which consists of membrane filtration coupled to a UV disinfection system. Furthermore, four pilot-scale constructed wetlands are installed; one aerated CW and three bio-electrified wetlands. The treated effluent from the pilot scale units is further processed through a sand filter and a UV disinfection unit.

The full-scale CW system is designed with two stages: 1st stage, saturated downflow VF (VF1 SAT); 2nd stage unsaturated intermittent load VF CW (VF2 UNSAT). Different recirculation options allow us to test up to 6 different configurations, investigating the best scheme to meet the National and also other Mediterranean regulations (e.g., different water quality standards for nitrogen). HYDRO1 establishes the optimal operating conditions under which COD removal and biogas production are maximized.